Nuclear-Grade Ion Exchange Resins: A Silent Catalyst in the Evolving Ion Exchange Resins Market

Nuclear-grade ion exchange resins are reshaping the market as rising nuclear energy demand sparks innovation, supply chain shifts, and regulatory focus.

NEWARK, DE, UNITED STATES, May 29, 2025 /EINPresswire.com/ -- The global ion exchange resins market—often synonymously referred to as the water softening resins market or industrial purification resin systems sector—has gained prominence due to its widespread application in water treatment, pharmaceuticals, food processing, and chemical separation. While typical discourse in this market revolves around municipal water treatment and boiler feed applications, a quieter but critically important segment is emerging: nuclear-grade ion exchange resins.

These highly specialized resins, used in nuclear power plants and radioactive waste management, are facing a demand surge driven by the global shift toward low-carbon energy and small modular reactors (SMRs). As the world re-embraces nuclear energy amid net-zero goals, the reliability and supply of nuclear resins have become a key strategic concern. This evolving pressure is reshaping supply chains, investment priorities, and even geopolitical alignments in the ion exchange resins market.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-1001

𝐓𝐡𝐞 𝐔𝐧𝐢𝐪𝐮𝐞 𝐑𝐨𝐥𝐞 𝐨𝐟 𝐍𝐮𝐜𝐥𝐞𝐚𝐫-𝐆𝐫𝐚𝐝𝐞 𝐑𝐞𝐬𝐢𝐧𝐬

Nuclear ion exchange resins are engineered to operate in high-radiation, high-temperature environments, often dealing with complex radioactive isotopes such as cesium-137, cobalt-60, and strontium-90. These resins are typically sulfonated polystyrene-divinylbenzene copolymers, designed with strict purity levels, controlled particle size distribution, and radiation-resistant backbones.

Unlike resins used in conventional water softening or demineralization, nuclear-grade resins are critical for decontaminating reactor coolant loops, purifying spent fuel pools, and treating liquid radioactive waste. Their failure could lead to operational delays or safety concerns in nuclear facilities—making their performance and reliability non-negotiable.

A real-world case underscores this importance: during the Fukushima disaster, improvised ion exchange systems using nuclear resins were deployed within days to remove cesium and reduce radiation in cooling waters. This demonstrated how strategic these materials can be in both planned and emergency nuclear operations.

𝐑𝐢𝐬𝐢𝐧𝐠 𝐃𝐞𝐦𝐚𝐧𝐝 𝐀𝐦𝐢𝐝 𝐍𝐮𝐜𝐥𝐞𝐚𝐫 𝐑𝐞𝐧𝐚𝐢𝐬𝐬𝐚𝐧𝐜𝐞

Global interest in nuclear energy is undergoing a revival. Countries like China, India, France, and the United Kingdom are investing billions into next-generation reactors, while the United States and Canada are pushing forward with SMRs that are safer and faster to deploy. This nuclear resurgence is directly translating into higher demand for advanced nuclear resins.

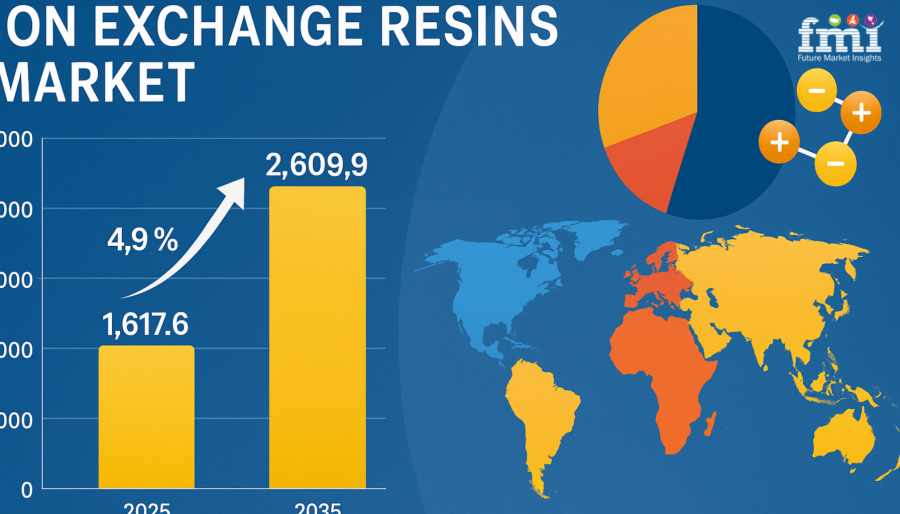

According to Future Market Insights, the Ion Exchange Resins Market is projected to grow from USD 1,617.6 million in 2025 to USD 2,609.9 million by 2035, reflecting a CAGR of 4.9% over the forecast period.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/ion-exchange-resins-market

This rising demand is not only stretching production capacities but also creating a strategic bottleneck—since only a handful of global suppliers, including Purolite (now part of Ecolab), Thermax, and LANXESS, are qualified to produce resins suitable for nuclear applications under ISO 9001 and NRC/IAEA standards.

𝐒𝐮𝐩𝐩𝐥𝐲 𝐂𝐡𝐚𝐢𝐧 𝐂𝐨𝐦𝐩𝐥𝐞𝐱𝐢𝐭𝐲 𝐚𝐧𝐝 𝐆𝐞𝐨𝐩𝐨𝐥𝐢𝐭𝐢𝐜𝐚𝐥 𝐑𝐢𝐬𝐤

The production of nuclear-grade resins is highly specialized, requiring pharmaceutical-grade facilities, rigorous testing, and long approval cycles. The supply chain involves sourcing high-purity monomers, precision polymerization, and stringent quality assurance—all within a framework of regulatory scrutiny and intellectual property restrictions.

Geopolitical tensions and trade restrictions are further complicating access to key raw materials like styrene and divinylbenzene, which are often sourced from specific regions. In 2023, a trade dispute between the EU and China disrupted the flow of polymer precursors, causing temporary shortages of high-grade resins in Europe.

Adding to the complexity is the fact that resin manufacturers must be certified by nuclear regulatory authorities, making rapid capacity expansions challenging. Even large industrial resin suppliers may be unable to enter the nuclear segment without years of investment and regulatory alignment.

𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐋𝐨𝐜𝐚𝐥𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐓𝐫𝐞𝐧𝐝𝐬

To mitigate supply risks and reduce foreign dependence, several countries are investing in domestic resin production and innovation. India’s Department of Atomic Energy has partnered with local resin manufacturers to develop indigenous nuclear-grade resins, with successful trials reported at the Tarapur Atomic Power Station.

𝐆𝐞𝐧𝐞𝐫𝐚𝐥 & 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

In the U.S., the Department of Energy is funding research into novel composite resins that incorporate inorganic nanoparticle additives for enhanced radiation stability and ion selectivity. These resins aim to be both safer and longer-lasting, reducing the frequency of replacement and radioactive waste generation.

Meanwhile, additive manufacturing and continuous polymerization techniques are being explored to reduce production time and cost without compromising quality—signaling a potential disruption in how nuclear resins are manufactured in the next decade.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐚𝐧𝐝 𝐑𝐞𝐠𝐮𝐥𝐚𝐭𝐨𝐫𝐲 𝐎𝐮𝐭𝐥𝐨𝐨𝐤

The rising strategic importance of nuclear-grade ion exchange resins is prompting new frameworks for procurement and regulation. International alliances like the Nuclear Energy Agency (NEA) are exploring joint procurement programs to ensure stable supply among member nations, similar to how critical medical isotopes are jointly sourced.

From a commercial perspective, buyers in the nuclear sector are increasingly demanding long-term fixed contracts with resin suppliers, favoring vertically integrated companies that offer turnkey purification systems and post-use disposal support. This shift in procurement behavior is gradually driving a realignment of revenue streams in the ion exchange resins market—from product sales to long-term service contracts.

Moreover, nuclear regulators are now encouraging power plants to factor resin lifecycle management into their license applications, linking resin performance directly to reactor safety and operational approvals.

𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Product Type:

- Cation Exchange Resins

- Anion Exchange Resins

- Others

By End Use:

- Power Generation

- Chemical and Fertilizer

- Food and Beverage

- Electrical and Electronics

- Pharmaceutical

- Domestic and waste water treatment

- Paper and Pulp

- Others

By Region:

- North America

- Latin America

- Europe

- East Asia

- South Asia

- Oceania

- Middle East & Africa (MEA)

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Pour Point Depressants Market: https://www.futuremarketinsights.com/reports/pour-point-depressants-market

Terephthalic Aldehyde Market: https://www.futuremarketinsights.com/reports/terephthalic-aldehyde-market

Epoxy Curing Agent Market: https://www.futuremarketinsights.com/reports/epoxy-curing-agents-market

OEM Insulation Market: https://www.futuremarketinsights.com/reports/oem-insulation-market

Magnesium Chloride Market: https://www.futuremarketinsights.com/reports/magnesium-chloride-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 5000 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release